CNC Machining Technology is a technique that utilizes computer control over machine tools for processing, characterized by high precision, fast efficiency, and excellent flexibility. It has found widespread applications in the manufacturing industry. This article will introduce the principles, advantages, and applications of CNC machining technology. If needed, feel free to seek collaboration with CHATRONIC, the most professional company in the market.

What is CNC Machining?

CNC machining is a technique that utilizes computer control over machine tools for processing. To put it simply, it involves instructing the machine via computer commands on how to perform tasks, after which the machine autonomously carries out the processing.

Advantages of CNC Machining Technology

There are numerous advantages to CNC machining, including:

- High precision: CNC machining can achieve precise processing according to computer instructions, with processing accuracy reaching the micron level.

- Fast efficiency: CNC machining automates the processing process, enhancing processing efficiency.

- Excellent flexibility: CNC machining can fulfill different processing requirements through computer instructions, exhibiting good flexibility.

Principles of CNC Machining Technology

The principle of CNC machining involves controlling the movement of machine tools using a computer and processing the workpiece according to pre-coded instructions. The control system of CNC machining technology mainly consists of the following components:

- Digital controller: The digital controller is the core component of CNC machining technology, responsible for controlling the movement of the machine tool. The digital controller typically consists of a central processing unit (CPU), memory, input/output (I/O) interfaces, etc.

- Servo system: The servo system is the executing mechanism of the digital controller, responsible for translating the instructions issued by the controller into the movement of the machine tool. The servo system typically consists of servo motors, drivers, encoders, etc.

- Computer program: Engineers use computer programs to design and write CNC machining procedures.

Encoding Process of CNC Machining

The encoding process of CNC machining involves converting machining requirements into computer instructions. CNC machining programs typically consist of the following parts:

- Preparation program: The preparation program is mainly used to define machining parameters, such as the material, size, and machining accuracy of the workpiece.

- Machining program: The machining program is mainly used to describe the specific steps of machining, such as tool selection, cutting speed, feed rate, etc.

- Finishing program: The finishing program is mainly used to indicate the actions to be taken after machining is completed, such as machine tool retraction, etc.

Applications of CNC Machining Technology

CNC machining technology has been widely used in the manufacturing industry, mainly in the following fields:

- Mechanical machining: CNC machining technology can be used for processing various mechanical parts, such as turning parts, milling parts, grinding parts, etc.

- Mold manufacturing: CNC machining technology can be used for manufacturing various molds, such as plastic molds, stamping molds, etc.

- Electronics manufacturing: CNC machining technology can be used for manufacturing various electronic components, such as circuit boards, connectors, etc.

- Aerospace: CNC machining technology can be used for manufacturing various aerospace parts, such as aircraft parts, spacecraft parts, etc.

Introduction to CNC Equipment Owned by CHATRONIC

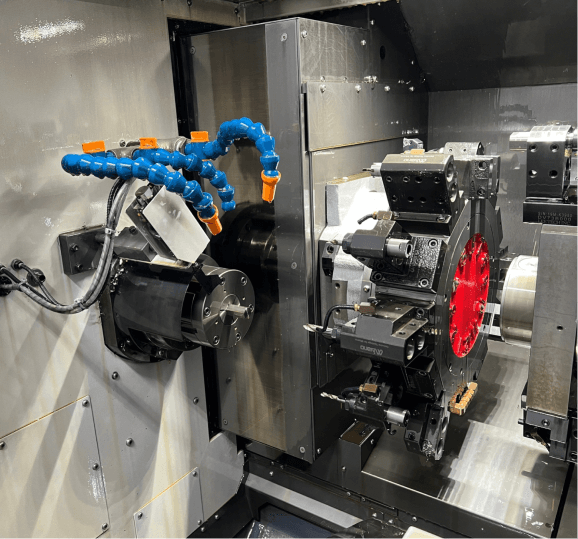

Below is an introduction to the CNC equipment owned by our company. CHATRONIC possesses over 40 CNC turning and milling composite processing (SWISS TYPE & FIXED HEAD) equipment, capable of processing diameters ranging from Ø3mm to Ø51mm.

CHATRONIC possesses both Swiss-type and turret-type CNC turning and milling composite processing equipment. In addition to being widely applicable across various industries and materials such as stainless steel, iron, aluminum, copper, etc., these machines are capable of performing a range of precision machining processes, including turning, milling, drilling, tapping, and more.This allows for a one-stop solution, reducing processing time and increasing production efficiency.

Common applications include fiber optic components, pneumatic tool parts, medical product components, automotive parts, etc.

Recommended by CNC Company: CHATRONIC

CHATRONIC was founded in 1987, originally employing traditional lathe production methods. After many years of development, the company has transformed into a fully automated production process. CHATRONIC has consistently relied on professional expertise and outstanding quality, continuously enhancing competitiveness to ensure the company’s sustainable development.

Today, CHATRONIC is headquartered in Xizhi District, New Taipei City, with a professional factory covering an area of 400 square meters. It houses over 40 CNC turning and milling composite machines, as well as a team of experienced technicians and inspection instruments. Feel free to contact us for service!